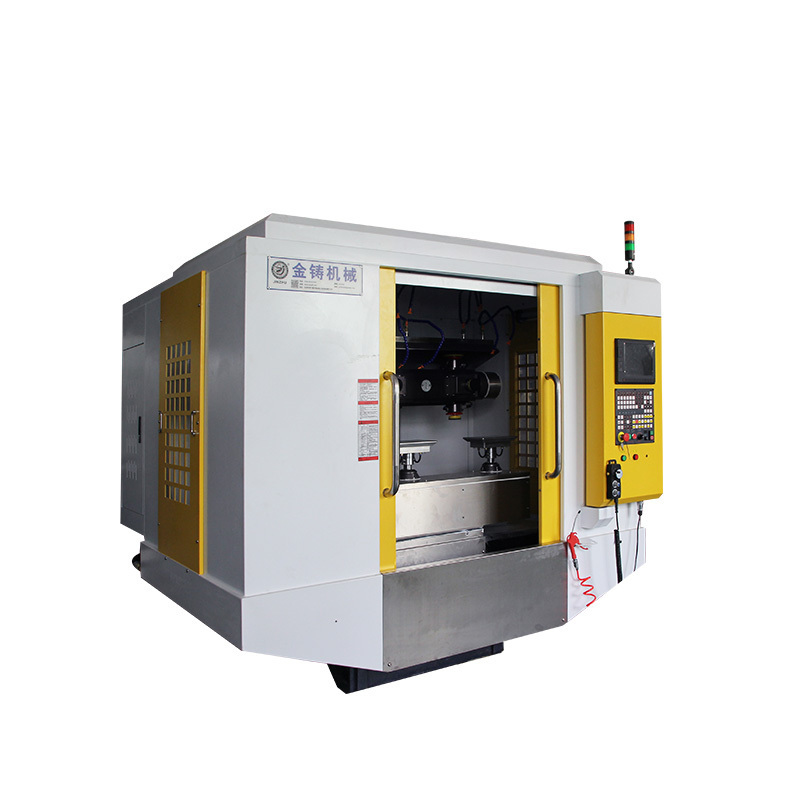

Vertical Automatic Specialized Polishing Machining Center

| Product Name |

Vertical Automatic Specialized Polishing Machining Center Automatic 4 Axis CNC Vertical Machining Center |

| Core Components |

PLC, Engine, Motor |

| Power (kW) |

10 |

| Weight (KG) |

2000 |

| Key Selling Points |

Automatic |

| Warranty |

1 Year |

| Applicable Industries |

Machinery Repair Shops, Manufacturing Plant |

| Technical Specifications |

- X-axis route: 250mm

- Y-axis route: 450mm

- Z-axis route: 350mm

- A-axis route: -1°~365°

- C-axis route: -30°~390°

- Rotary table: 192mm

- Rotating Speed: 0~10000

- X Y Z Fast-forward speed: 25X25X20

- Positioning: ±0.025

- Power supply: 380V-10KVA

|

Product Features

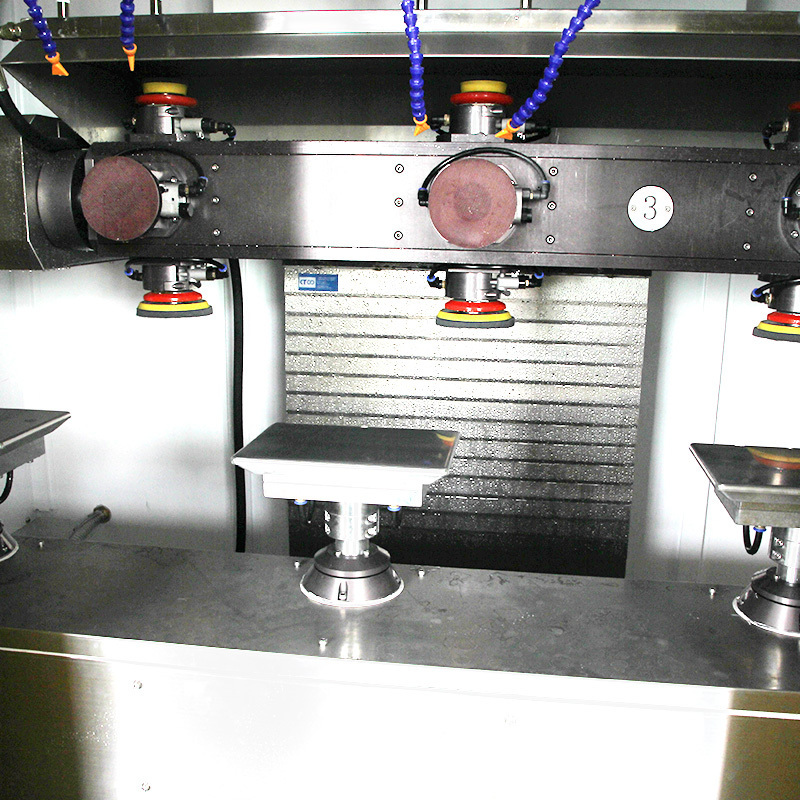

This equipment is a five-axis linkage CNC polishing machine with CNC control system that programs according to product outline. The product is manually fixed on the fixture (vacuum suction) and precision motor is driven by G code to move according to product profile.

Key Features:

- Five work turntables move synchronously, processing five identical workpieces simultaneously

- Adapted for grinding cell phone shell arc surfaces and side arc surfaces

- High productivity with stable quality output

- Dust-free operation with no risk of dust explosion (spray system)

- Clean environmental protection system

Automated Procedure Overview:

The machine features CNC control system with five-axis linkage motion profile, high-precision interpolation, and high-speed response. It uses high-precision, high-power servo motor drive and models products according to their own profile. The rotating vibration polishing wheel with sandpaper polishes the product, with water added for dust suppression, cooling, and decontamination.

Electrical Control Overview:

- System controls entire machine for automatic grinding

- Automatic control, monitoring, counting, and alarm functions

- Single-action operation available for machine adjustment

- Different graphic G code can be imported for different products

Technical Requirements:

- Power supply: Three-phase 380V 50/60Hz 8.5 KVA

- Air pressure: Factory air pressure ≥0.4 Mpa (dry air required)

- Gas consumption: ≥40L/min

- DC power supply: 24V-200W

Frequently Asked Questions

Q: Are you a factory or a trader?

A: We are a manufacturer (factory)

Q1: Our company's history and background?

A1: DongGuan Jinzhu Machine Equipment Co., Ltd was founded in 2006, focusing on the research and development, production, and sales of industrial machinery and equipment, with over 15 years of industry experience.

Q2: Our company culture?

A2: We adhere to the core values of "innovation, quality, and service" and are committed to providing customers with the highest quality mechanical equipment and solutions.

Q3: How to view the current development trend of the machinery industry?

A3: We believe that intelligence, automation, and green environmental protection are the main development trends in the current machinery industry.

Q4: What are your main products?

A4: We mainly produce industrial machinery and equipment, including automatic polishing machines, automatic wire drawing machines, automatic spinning machines, etc.

Q5: How to obtain technical support if the device malfunctions?

A5: You can submit a fault report through our customer service hotline or online technical support platform.

Q6: To which countries are the products mainly exported?

A6: Our products have been exported to multiple countries including Europe, North America, and Southeast Asia.

Q7: Do you accept customized requirements?

A7: Yes, we accept customized needs from customers.

Q8: How to conduct product procurement?

A8: You can obtain product quotations through our official website or by contacting a sales representative.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!